One Click or Two

Is double clicking of a torque wrench, good or poor practice?

The workhorse for many assembly tasks is the clicker torque wrench. Such a wrench allows you to set a torque value so that when the applied torque reaches that value, the wrench clicks and deflects a few degrees on a spring so that no further torque is applied. Assuming that is, the person senses this and stops applying the torque. Some people in the industry report that you shouldn't double click since it can result in too high a torque being applied, a 20% increase in torque on the second click in one video. For some previous tests for a client, Bolt Science had been requested to do such double torquing (we were using a torque transducer rather than a clicker wrench). In that instance, no benefit was gained by applying a second torque shortly after the first.

The workhorse for many assembly tasks is the clicker torque wrench. Such a wrench allows you to set a torque value so that when the applied torque reaches that value, the wrench clicks and deflects a few degrees on a spring so that no further torque is applied. Assuming that is, the person senses this and stops applying the torque. Some people in the industry report that you shouldn't double click since it can result in too high a torque being applied, a 20% increase in torque on the second click in one video. For some previous tests for a client, Bolt Science had been requested to do such double torquing (we were using a torque transducer rather than a clicker wrench). In that instance, no benefit was gained by applying a second torque shortly after the first.

To clarify the effect of double clicking the torque wrench has on both the bolt preload and the applied torque, Bolt Science completed some tests. The tests are detailed below, but the conclusions drawn from the tests are:

To clarify the effect of double clicking the torque wrench has on both the bolt preload and the applied torque, Bolt Science completed some tests. The tests are detailed below, but the conclusions drawn from the tests are:

Conclusions

The tests can be criticized as being too limited, but we think some conclusions can be drawn.

On a metal to metal joint, double clicking, even after waiting for a small period to ensure that the correct torque is applied, would seem superfluous, based upon these tests at least. Effort should be centred on ensuring that the optimum torque is specified and then correctly applied. On a metal to metal joint, double clicking, even after waiting for a small period to ensure that the correct torque is applied, would seem superfluous, based upon these tests at least. Effort should be centred on ensuring that the optimum torque is specified and then correctly applied.

Double clicking in rapid succession is likely to result in a higher than specified torque being applied. This is due to the spring in the wrench being overcome and the wrench acting as a breaker bar. Hence such practice cannot be recommended. Double clicking in rapid succession is likely to result in a higher than specified torque being applied. This is due to the spring in the wrench being overcome and the wrench acting as a breaker bar. Hence such practice cannot be recommended.

If double clicking is to be used, for whatever reason, applying the second click too fast can result in the bolt being over-torqued. Hence, it is necessary to delay the second torque application so that the torque acting on the fastener returns to zero, before the second torque is applied. If double clicking is to be used, for whatever reason, applying the second click too fast can result in the bolt being over-torqued. Hence, it is necessary to delay the second torque application so that the torque acting on the fastener returns to zero, before the second torque is applied.

With a soft joint, such as one containing a gasket, there is evidence that applying a second torque operation will reduce the preload loss from creep. Longer the delay before the second torque is applied, the greater the loss recovery. With a soft joint, such as one containing a gasket, there is evidence that applying a second torque operation will reduce the preload loss from creep. Longer the delay before the second torque is applied, the greater the loss recovery.

To achieve the correct torque application, rotate the wrench in a slow, deliberate manner until the correct torque is achieved. To achieve the correct torque application, rotate the wrench in a slow, deliberate manner until the correct torque is achieved.

Be aware, that to increase or to recovery any preload lost by short term relaxation, by re-torquing, some rotation of the nut will occur.

These tests were completed on a joint with a single bolt. There can be good reason on a multi-bolt joint in tightening the bolt in a sequence, and more than once. Elastic interaction, changing the load in one bolt when the one next to it is tightened, usually requires multiple torque applications to the same bolt. This is slightly different to what was investigated here. Be aware, that to increase or to recovery any preload lost by short term relaxation, by re-torquing, some rotation of the nut will occur.

These tests were completed on a joint with a single bolt. There can be good reason on a multi-bolt joint in tightening the bolt in a sequence, and more than once. Elastic interaction, changing the load in one bolt when the one next to it is tightened, usually requires multiple torque applications to the same bolt. This is slightly different to what was investigated here.

Details about the tests

There is some dispute on whether double clicking is a good practice, or whether it is best avoided. The action of re-applying the same torque value is sometimes referred to as double torquing and there are a few reasons why some people believe that it is good practice. One belief is that it recovers the bolt preload loss from relaxation that can occur when tightening stops. Such loss is typically due to embedding on a solid joint or creep on a joint with gasket present. Another belief is that some people want to double click just to make sure that the correct torque was reached.

To investigate the efficacy of double clicking, a series of tests were conducted in which both the applied torque and the bolt preload were simultaneously measured. The applied torque was measured by inserting a torque transducer between the wrench and the socket. The bolt preload was measured by inserting a load cell in the joint. The tests were completed on M12 property class 10.9 bolts with the clicker wrench set to a nominal value of 100 Nm. Two types of joints were investigated. The first a solid metal joint and the second, a joint with a rubber gasket present. Such a joint is referred to as a 'soft' joint since its stiffness will be low, relative to the all-metal joint, due to the presence of the gasket. In all cases the nut was rotated. To assess the preload drop-off, the preload reading was made 30 seconds after applying the second torque application.

Single click test on a metal-to-metal joint

In this test, just a single click was used. As you can see, from the graphs, the torque applied was accurate and little reduction in the bolt preload occurred over a 30 second period. No washers were used in the joint (experience indicates that more loss occurs when washers and additional surfaces are present in the joint). From previous tests and published research, the installed preload in a solid metal-to-metal joint will be retained until the joint sustains some applied loading, or the temperature significantly changes. When such change occurs, some further preload loss occurs as the pressure on the interfaces change and further embedding occurs. The embedding loss is asymptotic, that is, the loss does not continue indefinitely but reaches a limiting value.

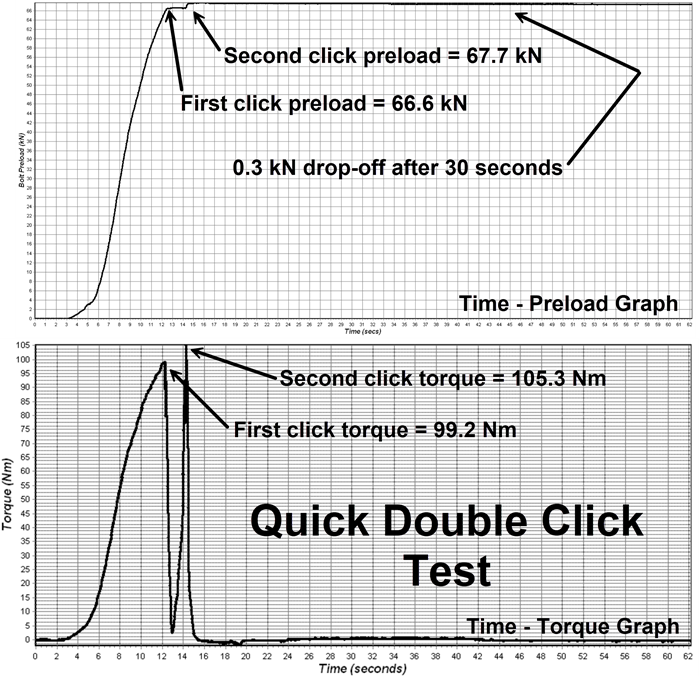

Quick double click test on a metal-to-metal joint

In this test, two applications of the torque were made in rapid succession. The set torque was within the expected value when the first click was applied. When the second click, the bolt was over torqued exceeding the set value by over 5%. The preload increased slightly due to the higher second torque value being applied. The preload drop-off over a 30 second period was again small.

The torque was allowed to drop to close to zero before applying the second torque. If the torque was more rapidly applied so that the torque didn't drop off as much, it is likely that the spring would be overcome, and wrench would act as a breaker bar and the torque applied would be significantly greater than 100 Nm.

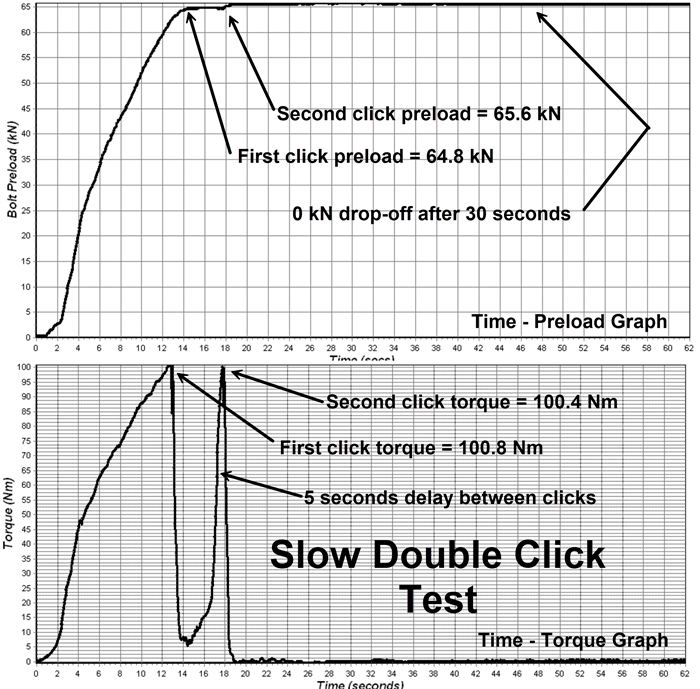

Slow double click test on a metal-to-metal joint

In this test, the second click was applied after a 5 second delay. The second application of the torque was within expected margin with the preload increasing slightly. (Whether the preload increases depends upon the specific friction conditions on the nut face and in the thread for that tightening.)

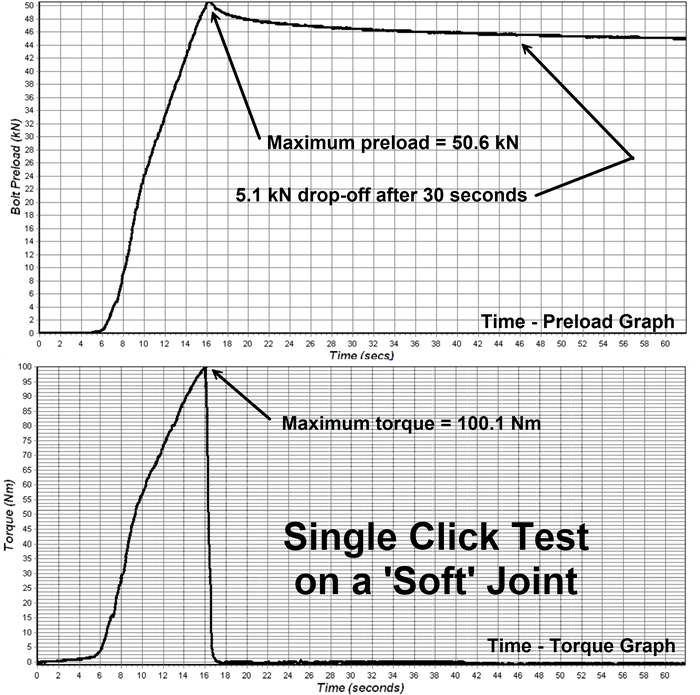

Single click test on a 'soft' joint

In order to assess the effect when the preload drops off more rapidly, a rubber gasket was placed in the joint. When clamped, creep occurs to the gasket reducing the gasket thickness and so subsequently, the bolt elongation and hence the preload. As can be seen from the results below, the preload drop-off can be significant.

Double click test on a 'soft' joint with a 5 second delay between clicks

In this test on a 'soft' joint, the second torque application/click was applied 5 seconds after the first. Both torque values are within expected limits. Within the 5 seconds 2 kN of preload was lost that was recovered by the application of the second click. Relative to the single click test, the preload loss 30 seconds after the torque application was reduced from 5.1 kN to 2.3 kN.

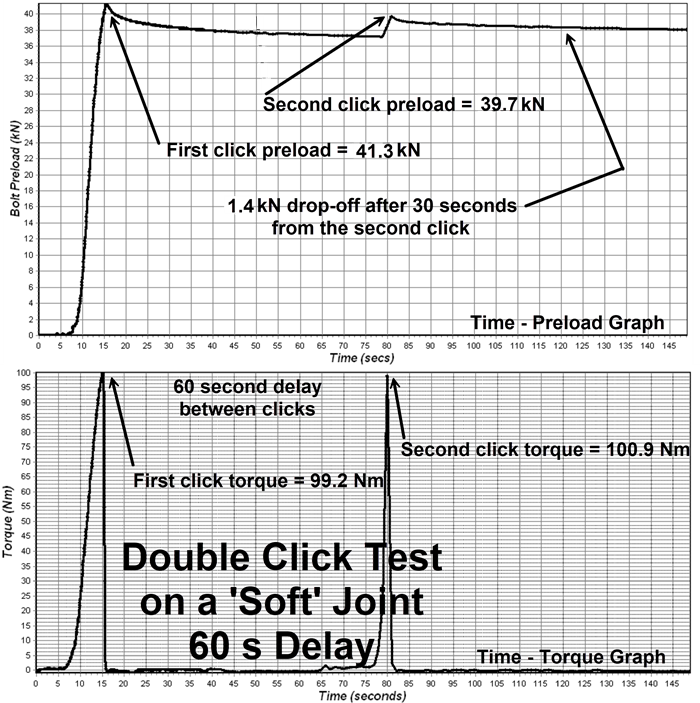

Double click test on a 'soft' joint with a 60 second delay between clicks

In this test, a second click was applied 60 seconds after applying the first. Relative to the single click test, and the 5 second delay click test, the preload loss 30 seconds after the torque application was reduced from 5.1 kN and 2.3 kN respectively, to 1.4 kN.

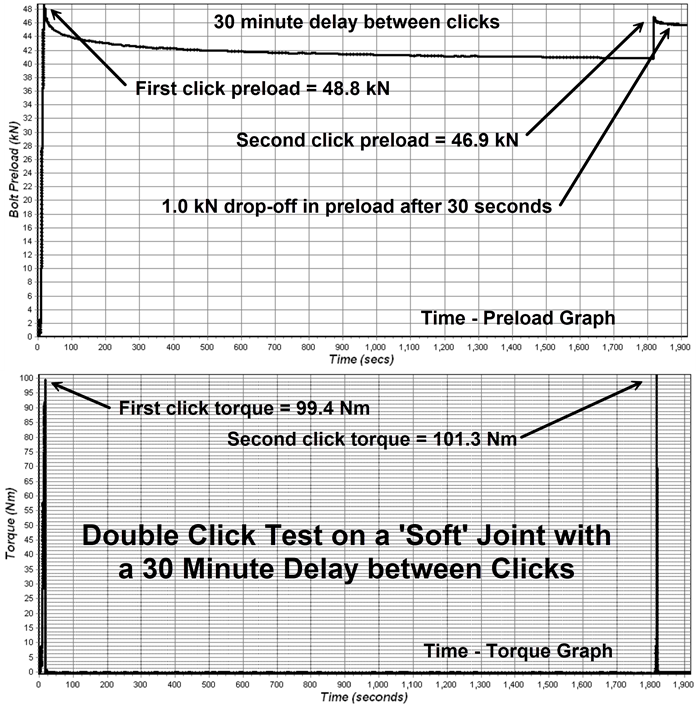

Double click test on a 'soft' joint - 30 minutes between clicks

In this test, a second click was applied 30 minutes after applying the first torque. Not so much as a double click, more of a re-torquing exercise. Again, the applied torque values were within expected limits. Relative to the single click test, and the double clicking tests, the preload loss 30 minutes after the last torque application was further reduced to 1 kN.

These tests could be extended by studying different joint types. For instance, fasteners using wedge lock washers do experience increased short term relaxation loss relative to a plain washer, but it is uncertain as whether double clicking, even after a delay, would be desirable or detrimental in such a case.

These tests could be extended by studying different joint types. For instance, fasteners using wedge lock washers do experience increased short term relaxation loss relative to a plain washer, but it is uncertain as whether double clicking, even after a delay, would be desirable or detrimental in such a case.

|