Training

Distance Learning Course: Bolting Technology for Engineers

and Designers

Bolt Science has developed a distance learning

course on Bolting Technology for Engineers and Designers.

The training is:

1. Completely online and can be taken

whilst at work on a PC, or if you wish, from home or other location

using a laptop,or a tablet device such as an iPad.

2 . The training is made up of a number of presentations on

various topics which include exercises and quizzes.

3 . The pace at which you go through the training is up to you.

The LMS (Learning Management System) that the presentations

are linked to, will track your progress as you complete the

presentations and quizzes. There is a training handbook

presenting course notes, example calculations and tables that

the user can view and print out. Specific details of the course

content is presented in the PDF brochure.

The course is designed for Engineers and Designers who are responsible

for the specification and design of bolted joints. This is a

practical course, in that methodologies are presented for solving

everyday bolting problems encountered in mechanical engineering.

There is a course completion certificate available to those

who pass an end of course test.

Courses can be held at your organisations

premises. If you are interested in this course, further details

are available in the course brochure that can be downloaded

by clicking on the link below:

View

the Brochure: Bolting Technology for Engineers and Designers

View

the Brochure: Bolting Technology for Engineers and Designers

Background

Threaded fasteners are a notable

cause of service and other related problems. Besides possible

safety implications, fastener failures can represent a significant

proportion of a product's warranty costs. This online distance

learning course presents key knowledge and facts to an Engineer

to enable bolted joints to be designed and fasteners sized

so that they will not fail.

This online distance learning course

is designed for:

OEM Designers

Design Engineers.

Project Leaders.

Engineers with responsibility for solving service problems.

Engineering Supervisors

Engineering Managers

Key benefits of this training

This online distance learning course

will help you to

1. Determine the appropriate size and strength of fastener

to be used in an application.

2. Understand the common modes of failures of fasteners and

how each mode can be prevented.

3. Be able to calculate the loading acting on individual bolts

given the forces acting on the joint.

4. Avoid the pain of making very costly, unnecessary mistakes

when designing bolted joints.

5. Learn the differences between a manufacturing and design

quality defect in relation to threaded fasteners.

6. Be able to determine the appropriate tightening torque

to specify for a threaded fastener in a given situation.

7. Be able to establish the length of thread engagement needed

to prevent thread stripping.

8. Be able to determine the forces acting on individual bolts

when forces are acting on a joint.

Course Documentation

A training course handbook is provided

as part of the training that can be viewed online and printed

out, if required. The handbook contains background information

to the material presented on the course, including derivation

of the formulas, example calculations together with tables

of thread stress areas, thread shear areas and fastener material

strength details. Following presentation of the background

theory, delegates are presented with problems relating to

the topic. Full answers are provided in the course documentation.

Course Agenda and Contents

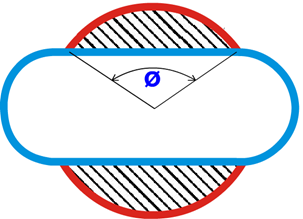

Introduction to Threaded Fasteners

Some

thread terminology. Some

thread terminology.

Background

to modern threads - Whitworth, Sellers and metric threads. Background

to modern threads - Whitworth, Sellers and metric threads.

Fine

and coarse thread and the advantages/disadvantages of each. Fine

and coarse thread and the advantages/disadvantages of each.

The

basic profile of Unified and metric thread forms. The

basic profile of Unified and metric thread forms.

Thread

tolerance positions and grades and tolerance classes. Thread

tolerance positions and grades and tolerance classes.

The

stress area, what it is and how is it derived. The

stress area, what it is and how is it derived.

Strength of bolts

The

principles of bolt elongation, bolt stress and load. The

principles of bolt elongation, bolt stress and load.

Yield,

tensile strength and proof load properties. Yield,

tensile strength and proof load properties.

Details of common bolting specifications.

Details of common bolting specifications.

Upper and lower strength limits for bolts.

Upper and lower strength limits for bolts.

Bolt and nut head markings and identification of correct

components.

Bolt and nut head markings and identification of correct

components.

Stainless steel fasteners ISO 3506, Duplex and Super Duplex.

Stainless steel fasteners ISO 3506, Duplex and Super Duplex.

Nut/bolt combinations, nut strength versus bolt strength.

Nut/bolt combinations, nut strength versus bolt strength.

Upper and lower temperature limitations of common bolting

materials.

Upper and lower temperature limitations of common bolting

materials.

Why bolts should be tightened

The

"Bolted Joint Enigma“ and why is tightening a

bolt important? The

"Bolted Joint Enigma“ and why is tightening a

bolt important?

How a preload joint sustains an axial load.

How a preload joint sustains an axial load.

Joint separation – what is it and why is it important.

Joint separation – what is it and why is it important.

Why tightening bolts is important for shear loaded joints.

Why tightening bolts is important for shear loaded joints.

Explanation of why the bolt sustains a small proportion

of an axial load.

Explanation of why the bolt sustains a small proportion

of an axial load.

A case study.

A case study.

Fastener Failure Modes

Overview

of the ways threaded fasteners can fail. Overview

of the ways threaded fasteners can fail.

Manufacturing Related Quality Defects.

Manufacturing Related Quality Defects.

Design Related Quality Defects.

Design Related Quality Defects.

Failure by insufficient preload.

Failure by insufficient preload.

Fatigue failure of bolts.

Fatigue failure of bolts.

Thread Stripping Failures - internal and external threads.

Thread Stripping Failures - internal and external threads.

Bolt overload from applied forces.

Bolt overload from applied forces.

Bearing stress under the bolt head or nut face.

Bearing stress under the bolt head or nut face.

Methods of Tightening Threaded Fasteners

Overview

of the methods used to tighten bolts. Overview

of the methods used to tighten bolts.

Load-angle of turn graph for a bolt tightened to failure.

Load-angle of turn graph for a bolt tightened to failure.

Torque controlled tightening method.

Torque controlled tightening method.

Torque-angle tightening below the yield point.

Torque-angle tightening below the yield point.

Projected angle tightening method below the yield point.

Projected angle tightening method below the yield point.

Yield point tightening using incremental angle method.

Yield point tightening using incremental angle method.

Yield point tightening method using slope measurement.

Yield point tightening method using slope measurement.

Torque-angle tightening method into the plastic region.

Torque-angle tightening method into the plastic region.

Yield control tightening plus an angle increment.

Yield control tightening plus an angle increment.

Limited re-use of bolts sustaining plastic deformation.

Limited re-use of bolts sustaining plastic deformation.

Bolt tensioning using hydraulic tensioning method.

Bolt tensioning using hydraulic tensioning method.

Tightening by elongation measurement.

Tightening by elongation measurement.

Heat tightening of large bolts

Heat tightening of large bolts

Tension indicating methods using load indicating bolts and

washers.

Tension indicating methods using load indicating bolts and

washers.

Use of ultrasonic's for bolt tightening.

Use of ultrasonic's for bolt tightening.

Torque Control

What is meant by a tightening torque. Units used to measure

torque.

What is meant by a tightening torque. Units used to measure

torque.

What are the consequences of not applying sufficient torque

to a bolt.

What are the consequences of not applying sufficient torque

to a bolt.

How torque is absorbed by a nut/bolt assembly.

How torque is absorbed by a nut/bolt assembly.

The torque-tension graph.

The torque-tension graph.

The relationship between the tightening torque and bolt

preload.

The relationship between the tightening torque and bolt

preload.

The factors which affect the torque-tension relationship.

The factors which affect the torque-tension relationship.

The nut factor method of determining the correct tightening

torque.

The nut factor method of determining the correct tightening

torque.

How to determine the appropriate tightening torque.

How to determine the appropriate tightening torque.

Example calculation of how to determine the correct tightening

torque.

Example calculation of how to determine the correct tightening

torque.

Scatter in the bolt preload resulting from friction variations.

Scatter in the bolt preload resulting from friction variations.

Determining the bolt preload (tension) resulting from a

tightening torque.

Determining the bolt preload (tension) resulting from a

tightening torque.

Prevailing torque fasteners and how it affects the torque

distribution.

Prevailing torque fasteners and how it affects the torque

distribution.

Tests to determine the coefficient of friction of threaded

fasteners.

Tests to determine the coefficient of friction of threaded

fasteners.

Self-Loosening of Threaded Fasteners

Non-rotational loosening (relaxation) and rotational loosening

(self-loosening).

Non-rotational loosening (relaxation) and rotational loosening

(self-loosening).

Have an overview of the research completed over the last

50 years into establishing the cause of the self-loosening

of threaded fasteners.

Have an overview of the research completed over the last

50 years into establishing the cause of the self-loosening

of threaded fasteners.

Appreciate the forces that are acting on the threads that

tend to self loosen a fastener. Why fine threads can resist

loosening better than coarse threads. The inclined plane

analogy.

Appreciate the forces that are acting on the threads that

tend to self loosen a fastener. Why fine threads can resist

loosening better than coarse threads. The inclined plane

analogy.

Learn about the work completed by Goodier and Sweeney into

loosening due to variable axial loading.

Learn about the work completed by Goodier and Sweeney into

loosening due to variable axial loading.

The work completed by ESNA and the theory of shock induced

loosening and resonance within fasteners.

The work completed by ESNA and the theory of shock induced

loosening and resonance within fasteners.

The NASM 1312-7 vibration test for fasteners.

The NASM 1312-7 vibration test for fasteners.

Junker’s theory on self-loosening of fasteners and

why fasteners self-loosen.

Junker’s theory on self-loosening of fasteners and

why fasteners self-loosen.

The Junkers/transverse vibration test for fasteners.

The Junkers/transverse vibration test for fasteners.

The influence that vibration amplitude has on the fastener

self-loosening rate.

The influence that vibration amplitude has on the fastener

self-loosening rate.

Preload decay curves and the effectiveness of various fastener

types in resisting vibrational loosening.

Preload decay curves and the effectiveness of various fastener

types in resisting vibrational loosening.

The findings of Haviland and Kerley and how fasteners can

come loose as a result of bending, shock or impact and differential

thermal expansion.

The findings of Haviland and Kerley and how fasteners can

come loose as a result of bending, shock or impact and differential

thermal expansion.

Conclusions from the research and how loosening can be prevented.

Conclusions from the research and how loosening can be prevented.

VDI 2230 Systematic Calculation of Bolted Joints

Why are systematic methods important?

Why are systematic methods important?

Development of Joint Diagrams.

Development of Joint Diagrams.

VDI 2230 Background and range of validity.

VDI 2230 Background and range of validity.

Key concepts of VDI 2230, failure modes of bolted joints

Key concepts of VDI 2230, failure modes of bolted joints

VDI 2230 - The Calculation Steps

VDI 2230 - The Calculation Steps

Initial bolt sizing

Initial bolt sizing

Determining the Tightening Factor

Determining the Tightening Factor

Determining the minimum clamp load

Determining the minimum clamp load

Determining the load factor

Determining the load factor

Relaxation/embedding loss in bolted joints

Relaxation/embedding loss in bolted joints

Effect of temperature change.

Effect of temperature change.

How to determine the minimum assembly preload

How to determine the minimum assembly preload

Determining the maximum assembly preload

Determining the maximum assembly preload

Establishing the bolt assembly stress

Establishing the bolt assembly stress

Determining the bolt working stress

Determining the bolt working stress

Establishing the alternating stress in the bolt

Establishing the alternating stress in the bolt

Importance of the bearing stress under the nut

Importance of the bearing stress under the nut

Thread stripping checks

Thread stripping checks

Joint slip and bolt shear stress

Joint slip and bolt shear stress

Limitations of VDI 2230

Limitations of VDI 2230

Software of VDI 2230 calculations

Software of VDI 2230 calculations

Preload Requirement Charts

How to prevent the majority of bolting issues.

How to prevent the majority of bolting issues.

Determining the maximum and minimum preloads.

Determining the maximum and minimum preloads.

How to calculate the likely embedding loss.

How to calculate the likely embedding loss.

Establishing the axial force requirement.

Establishing the axial force requirement.

Establishing the shear force requirement.

Establishing the shear force requirement.

Determining the total force requirement for the joint

Determining the total force requirement for the joint

Example calculations

Example calculations

Ways in which a bolting design problem can be resolved.

Ways in which a bolting design problem can be resolved.

Example problems for the student to resolve.

Example problems for the student to resolve.

Joint Bearing Pressure Calculations

Why is the bearing pressure important.

Why is the bearing pressure important.

Consequences of exceeding the limiting bearing pressure for the joint material.

Consequences of exceeding the limiting bearing pressure for the joint material.

Computing the bearing pressure under the bolt head or nut face.

Computing the bearing pressure under the bolt head or nut face.

Pressure cone principle that is used in the calculations.

Pressure cone principle that is used in the calculations.

Washer hardness and the consequences of getting this wrong.

Washer hardness and the consequences of getting this wrong.

The limiting bearing pressure for different joint materials.

The limiting bearing pressure for different joint materials.

Example bearing pressure calculations

Example bearing pressure calculations

Slotted holes and their effect on the bearing pressure.

Slotted holes and their effect on the bearing pressure.

Bearing area and bearing pressure calculations for slotted holes.

Bearing area and bearing pressure calculations for slotted holes.

Bolts in Direct Shear and Axially Loaded

Difference between a friction grip joint a joint with bolts

in direct shear.

Difference between a friction grip joint a joint with bolts

in direct shear.

Bolts in direct shear or is a friction grip joint is more

appropriate?

Bolts in direct shear or is a friction grip joint is more

appropriate?

Joints in single and double shear.

Joints in single and double shear.

The shear capacity of bolts in direct shear.

The shear capacity of bolts in direct shear.

The ratio of shear strength to tensile strength for steel.

The ratio of shear strength to tensile strength for steel.

How to determine the shear strength of bolts in direct shear.

How to determine the shear strength of bolts in direct shear.

Joints consisting of multiple bolts.

Joints consisting of multiple bolts.

Joints in direct shear and axially loaded as well.

Joints in direct shear and axially loaded as well.

Fatigue

of Threaded Fasteners Fatigue

of Threaded Fasteners

Background to fatigue failures.

Background to fatigue failures.

An explanation of what is fatigue.

An explanation of what is fatigue.

The causes of fatigue to be able to recognise this type

of failure.

The causes of fatigue to be able to recognise this type

of failure.

Beach marking and why fatigue failures usually occur in

the threads.

Beach marking and why fatigue failures usually occur in

the threads.

The S-N diagram and the endurance strength of a threaded

fastener.

The S-N diagram and the endurance strength of a threaded

fastener.

The load acting on a joint and that sustained by a bolt.

The load acting on a joint and that sustained by a bolt.

Approaches that to establish the endurance strength of a

threaded fastener.

Approaches that to establish the endurance strength of a

threaded fastener.

The effect that joint face angularity can have on the fatigue

performance of a fastener.

The effect that joint face angularity can have on the fatigue

performance of a fastener.

How the fatigue performance of a bolt can be improved.

How the fatigue performance of a bolt can be improved.

The effect that bolt diameter has on fatigue performance.

The effect that bolt diameter has on fatigue performance.

Thread Stripping

Identify the cause of thread stripping.

Identify the cause of thread stripping.

Be able to establish the shear area of an internal or external

thread.

Be able to establish the shear area of an internal or external

thread.

How the tapping drill size affects the strength of the bolt

thread.

How the tapping drill size affects the strength of the bolt

thread.

How the radial engagement of threads affects thread strength

and the failure load.

How the radial engagement of threads affects thread strength

and the failure load.

Use the information provided on the course to calculate

the internal and external thread areas and the force needed

to cause the threads to strip.

Use the information provided on the course to calculate

the internal and external thread areas and the force needed

to cause the threads to strip.

Be able to establish the length of thread engagement needed

to prevent thread stripping.

Be able to establish the length of thread engagement needed

to prevent thread stripping.

Example problems are presented together with questions for

the user to complete are provided – together with

full answers. stripping calculations so that you have confidence

to use them in practical applications.

Example problems are presented together with questions for

the user to complete are provided – together with

full answers. stripping calculations so that you have confidence

to use them in practical applications.

Galling of Threaded Fasteners

Background and explanation of galling.

Background and explanation of galling.

Types of fastener material and finishes susceptible to galling.

Types of fastener material and finishes susceptible to galling.

Examples of thread galling.

Examples of thread galling.

Approaches that are used to prevent/minimise galling.

Approaches that are used to prevent/minimise galling.

Shear Loads applied to Bolted Joints

What is meant by an eccentric shear load.

What is meant by an eccentric shear load.

Understand the slip process that can occur with shear loaded

joints.

Understand the slip process that can occur with shear loaded

joints.

Learn what is meant by the instantaneous centre of rotation

for the joint.

Learn what is meant by the instantaneous centre of rotation

for the joint.

Be able to calculate the reactions of individual bolts when

shear forces are applied to the joint.

Be able to calculate the reactions of individual bolts when

shear forces are applied to the joint.

Perform example calculations so that you have confidence

to use them in practical applications.

Perform example calculations so that you have confidence

to use them in practical applications.

Combined Tension and Shear Loading

What is meant by an eccentric shear load.

What is meant by an eccentric shear load.

Understand the slip process that can occur with shear loaded

joints.

Understand the slip process that can occur with shear loaded

joints.

Learn what is meant by the instantaneous centre of rotation

for the joint.

Learn what is meant by the instantaneous centre of rotation

for the joint.

Be able to calculate the reactions of individual bolts when

shear forces are applied to the joint.

Be able to calculate the reactions of individual bolts when

shear forces are applied to the joint.

Perform example calculations so that you have confidence

to use them in practical applications.

Perform example calculations so that you have confidence

to use them in practical applications.

Learn the methods that can be used to analyze joints subjected

to combined tension and shear loads.

Learn the methods that can be used to analyze joints subjected

to combined tension and shear loads.

Understand what is meant by prying and its effects.

Understand what is meant by prying and its effects.

Two methods that can be used to determine the neutral axis

of the joint when combined tension and shear loads are acting

Two methods that can be used to determine the neutral axis

of the joint when combined tension and shear loads are acting

Perform example calculations so that you have confidence

to use them in practical applications.

Perform example calculations so that you have confidence

to use them in practical applications.

Optional Material and Case Studies

Included in the training there are some optional modules. These include further details about certain technical aspects of bolting that are detailed below. Also included are some case studies of accidients drawn from various industry sectors. Catastrophic accidents have occurred as a result of the failure of bolted joints, they illustrate what can go wrong when bolted joints fail and what lessons can be learned. There is a course handbook provided as part of the training that can be viewed online and downloaded and printed. This material includes:

Case Study - Inadequate Tightening Resulting in Fatigue Failure of M27 Bolts.

Case Study - Inadequate Tightening Resulting in Fatigue Failure of M27 Bolts.

This case study looks at an application in which the bolts were inadequately tightened. This resulted in joint separation causing the bolts to sustain a higher dynamic load and stress.

Case Study - Fatigue Failure of Turbine Securing Bolts.

Case Study - Fatigue Failure of Turbine Securing Bolts.

This presentation describes the failure of 80 mm diameter fasteners failing by fatigue leading to a major accident at the Sayano-Shushenskaya Hydroelectric Power Station.

Case study of the fastener related causes of the derailment of a tanker train

Case study of the fastener related causes of the derailment of a tanker train

This case study discusses the fastener-related causes of a derailment and fire involving a tanker train at Llangennech, Carmarthenshire in Wales on 26 August 2020.

The Goldilocks Zone for the Coefficient of Friction (Optional Training).

The Goldilocks Zone for the Coefficient of Friction (Optional Training).

This training presentation is optional. The presentation discusses what is the ideal range for the coefficient of friction for threaded fasteners. Depending upon your previous training, some slides may contain material that you are familiar with. Such slides are repeated since they provide context for the work that will be subsequently presented.

Causes of Non-Linear Torque-Preload Relationships during Tightening (Optional Training).

Causes of Non-Linear Torque-Preload Relationships during Tightening (Optional Training).

This presentation covers the causes of non-linear torque-tension relationships during tightening. The presentation includes the effects of galling and the use of flange head fasteners.

Course Duration

The course represents 20 hours of

study (some people would complete in a shorter time, others

longer depending upon their previous experience and knowledge).

The course represents 2 continuing education units (based upon

10 hours of study per CEU). Access to the course will be available

for three months following the login and password details being

provided.

Course Director

Dr Bill Eccles is a mechanical engineer

with 40 years experience in mechanical engineering with the

last 20+ years specialising in bolted joint technology and analysis.

He is a Chartered Engineer and a Fellow of the Institution of

Mechanical Engineers and has a Doctorate in Engineering on the

self-loosening of threaded fasteners.

Bill has written several articles

on bolting technology and has developed bolted joint analysis

software that is used by major organisations around the world.

Order online (using a secure server) Order online (using a secure server)

|