The Causes of Non-Linear Torque-Tension Relationships during Tightening

When a nut is tightened by applying a torque, the bolt is stretched and a tensile force in the bolt, the preload, is created that resists this stretching. The preload is reacted by a clamp force on the joint. It is this clamp force that is vital in many instances for the joint's structural integrity. Since the preload is difficult to measure, the torque being applied to the fastener is used instead to assess that it has been sufficiently tightened. Ideally, we would measure the preload. But there is no low cost and effective method of doing so, hence torque control is the most common approach to controlling the bolt preload.

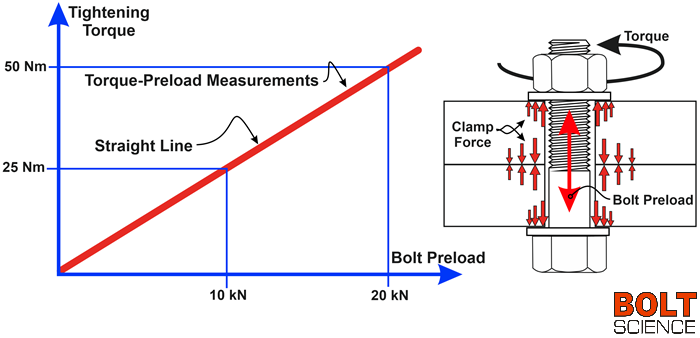

The relationship between the torque being applied and the bolt preload is linear. That is, when you plot out the relationship between the two by measuring both, you get a straight line as shown in the image. So, for a particular bolt if you double the applied torque, you will double the preload. Assuming that is, that the bolt material doesn't yield, or the thread starts to strip.

When a nut is tightened by applying a torque, the bolt is stretched and a tensile force in the bolt, the preload, is created that resists this stretching. The preload is reacted by a clamp force on the joint. It is this clamp force that is vital in many instances for the joint's structural integrity. Since the preload is difficult to measure, the torque being applied to the fastener is used instead to assess that it has been sufficiently tightened. Ideally, we would measure the preload. But there is no low cost and effective method of doing so, hence torque control is the most common approach to controlling the bolt preload.

The relationship between the torque being applied and the bolt preload is linear. That is, when you plot out the relationship between the two by measuring both, you get a straight line as shown in the image. So, for a particular bolt if you double the applied torque, you will double the preload. Assuming that is, that the bolt material doesn't yield, or the thread starts to strip.

This linear behaviour forms the basis of the torque calculation processes. For example, the simple K factor approach in which the formula T = F x D x K where T is the torque, D is the bolt diameter and K is the nut factor otherwise known as the torque coefficient. For a given bolt diameter and coating condition, K is assumed to be a constant and so the formula is essentially T ∝ F, that is, torque T is proportional to preload F. This is a straight line relationship between the applied torque and the preload. The same reasoning can be shown to apply to the long form version of the torque tension equation that uses friction coefficients instead of the K factor.

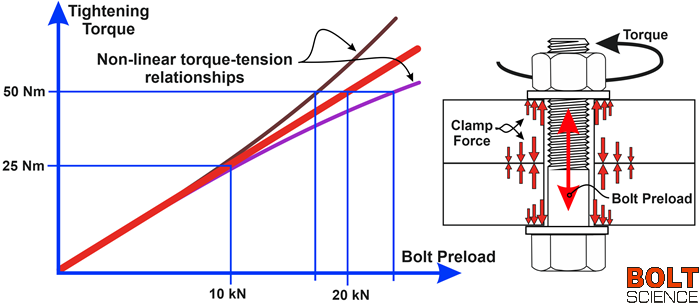

At Bolt Science we have conducted thousands of torque tension tests. Occasionally, we come across the situation where the graph of torque against preload is not linear, that is, the graph is a curve instead. The graph of torque against preload may curve upwards, or downwards, depending upon circumstances. This is illustrated in the image below.

When a nut is tightened, besides the tensile stress, the bolt is also subjected to torsion. This arises from the thread friction torque and the torque that is needed to stretch the bolt. Accordingly, higher the thread friction, higher will be the torsion in the bolt.

If the torque is now doubled, the preload can be greater than double, as in the case when the curve gradient is decreasing, or less than double, in the case when the curve gradient is increasing.

The causes of non-linear torque tension relationships are discussed in a recently published training presentation on the Bolting Technology for Engineers and Designers online course. Further details about the course are available here.

When a nut is tightened, besides the tensile stress, the bolt is also subjected to torsion. This arises from the thread friction torque and the torque that is needed to stretch the bolt. Accordingly, higher the thread friction, higher will be the torsion in the bolt.

If the torque is now doubled, the preload can be greater than double, as in the case when the curve gradient is decreasing, or less than double, in the case when the curve gradient is increasing.

The causes of non-linear torque tension relationships are discussed in a recently published training presentation on the Bolting Technology for Engineers and Designers online course. Further details about the course are available here.

|