Preload

Requirement Charts

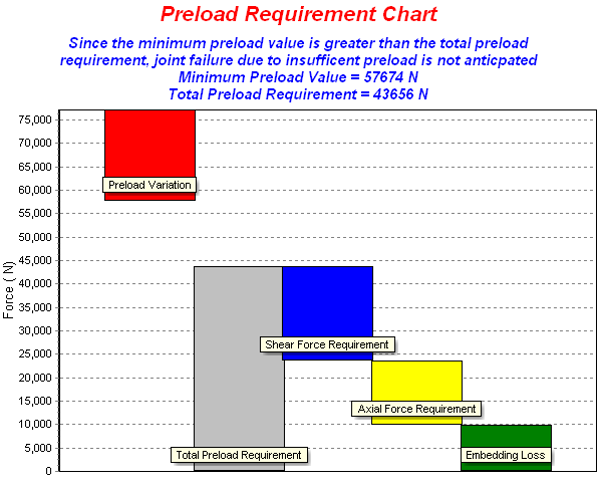

Joint diagrams can display a significant amount of information

about the joint but in our experience many people find them

difficult to interpret and understand. Preload Requirement

Charts are a way to graphically display the results of a joint

analysis in a clear and understandable manner.

By way of example, consider the joint

shown below that is subject to combined axial and shear loading.

For information, the bolt is M12 property class 10.9, the

joint thickness is 20 mm with an axial load of 15 kN and a

shear force of 4 kN being applied. (If the joint consists

of several bolts, it is first necessary to determine the loading

on an individual bolt.)

One key aspect to appreciate is that

the root cause of the majority of bolt/joint failures is due

to insufficient preload. It is unusual for the bolt to be overloaded.

If the preload provided by the bolt is insufficient, joint separation

and movement can occur resulting in possible bolt fatigue and

self-loosening issues. In order that such problems do not occur

it is vital that there is sufficient residual clamp force acting

on the joint interface after accounting for the effects of the

applied forces and embedding losses. A Preload Requirement Chart

graphically illustrates this point as it looks at the forces

acting on the joint interface. Such a chart is shown below for

the above joint.

The above chart was produced by the BOLTCALC

program, but such charts can be produced manually. Explaining

each of the parts of the chart in turn:

Embedding Loss: Embedding is localised

plastic deformation that occurs under the nut face, in the joint

faces and in the threads as a result of flattening of the surface

roughness. Embedding results in a loss of clamp force acting

on the joint. If the joint and bolt stiffness can be established,

the amount of this force loss can be quantified if the surface

roughness of the contact surfaces is defined. In the above chart,

a loss of 10 kN is anticipated. Large amounts of embedding loss

can occur in joints with a short grip length consisting of many

interfaces.

Axial Force Requirement: In a

preloaded joint, the majority of the applied axial load reduces

the clamp force on the joint interface rather than increasing

the load in the bolt (see an earlier tutorial

for an explanation). The amount of the axial load that unloads

the joint interface can be determined from the joint/bolt stiffness

calculations. In this example, of the 15 kN applied force, 13.8

kN reduces the clamp force on the interface (the remaining 1.2

kN increases the load in the bolt). To simplify, when hand calculations

are being completed, the conservative assumption is often applied

that all the applied axial load reduces the clamp force on the

joint interface.

Shear Force Requirement: The majority

of joints in mechanical engineering use clearance holes and

any shear load is transmitted by friction grip. That is, the

clamp force on the joint interface generates a friction force

that resists any applied shear loading. On such joints, if slippage

is prevented, the bolts do not directly sustain any shear loading,

however they have to provide sufficient clamp force to prevent

joint movement. To achieve this, the clamp force required is

the shear force divided by the coefficient of friction present

between the joint surfaces (for the single shear plane present

in the joint shown above). Since the coefficient of friction

is usually significantly less than 1, this requirement results

in a significantly larger clamp force being required than the

magnitude of the shear force. In this example, the applied shear

is 4 kN which, if a coefficient of friction of 0.2 is assumed

between the joint plates, results in a minimum clamp force of

20 kN (i.e. 4/0.2).

Total Preload Requirement: This

represents the minimum preload required to be provided by the

bolt. It is the sum of the embedding loss, the amount of the

applied axial force that reduces the clamp force on the joint

and the clamp force needed to prevent slippage of the joint

due to a shear loading.

Preload Variation: In an ideal

world the preload provided by the bolt would be known to an

exact value and would be the same for every bolt tightened.

Unfortunately there is no low cost means of tightening a bolt

and knowing, precisely, the preload value. Techniques such as

tightening the bolt to a specific torque value results in variation

in the preload between, apparently, identical bolts. This is

as a result of not being able to apply the torque to the same

exact value each time, variation in the hole and bolt tolerances

but more importantly, variation in the coefficient of friction

present in the threads and under the nut/bolt face. To design

a joint successfully this scatter in the preload must be taken

into account. This can be done in a number of ways but usually

either by determining the minimum/maximum preloads from knowledge

of the friction variation or by the use of a tightening factor.

The problem: In the above chart

the total preload requirement exceeds the minimum preload. What

this means is that on some, but not all joints, the preload

will be insufficient to resist the applied forces. In such cases,

joint failure can be anticipated. The failure is likely to be

by either bolt fatigue (due to bending due to the joint slipping

and separating) or by self-loosening (due to joint movement).

The solution: In general, changes

can be made to increase the minimum preload value (by using

a stronger or larger bolt or changing the tightening method)

or by reducing the applied forces (by using more bolts in the

joint, or by increasing the friction between the joint interface

and so reducing the shear force requirement etc.) Shown below

is the chart for changing the tightening method to torque and

angle. If applied correctly. this method will consistently provide

a high preload value.

Factor of Safety: A question which

often arises is how much of a gap there should be between the

total preload requirement and the minimum preload value. In mechanical engineering in which there are generally no design codes to stipulate the factor of safety, this

depends essentially upon engineering judgement. If the applied

forces are accurately known, if product testing is going to be

completed, then the gap can be small. If the forces are not

known accurately, and the consequences of failure disastrous,

then a larger gap would be sensible. The consequence of having

a generous factor of safety is that a larger bolt size (or higher

strength bolt or better tightening method etc.) would be needed

then which would otherwise be the case. This can result in a

more expensive and less competitive product.

Preload Requirement Charts can be developed to include other

effects such as the effect on bolt loading of differential thermal

expansion. They are a useful method for joint analysis and solving

bolting issues.

For the latest information on Bolt Science:

Click Here for Further details about

Bolt Science Training Courses

|