Helical

Spring Lock Washers

Helical spring lock washers have been in use for well over 100

years. They are still used on many applications in the belief

that they will will "lock" the nut/bolt to the joint

and prevent loosening. The body of evidence, based upon both

experience and experimental results, is that they do not prevent

loosening and can be shown to actually speed up the rate of

loosening in many cases. Junker originally showed in his work

published in 1969 that these washers are ineffective in preventing

loosening. Joints containing these washers have come loose resulting

in structural failure leading to both material and human loss.

Helical spring lock washers have been in use for well over 100

years. They are still used on many applications in the belief

that they will will "lock" the nut/bolt to the joint

and prevent loosening. The body of evidence, based upon both

experience and experimental results, is that they do not prevent

loosening and can be shown to actually speed up the rate of

loosening in many cases. Junker originally showed in his work

published in 1969 that these washers are ineffective in preventing

loosening. Joints containing these washers have come loose resulting

in structural failure leading to both material and human loss.

A series of tests were performed by Bolt Science to illustrate

the performance of this type of washer compared to a plain

nut by itself. The results are shown in the videos and in

the preload decay curve below. The preload decay curve is

from the tests shown in the video. The tests were performed

on M8 fasteners.

The test shown below is a test on a plain, non-locked nut. Under a Junker test such a nut will readily self-loosen.

A helical spring washer fails to prevent self-loosening. A video of a typical test is shown below.

I was recently asked under what circumstances would I recommend the use of helical spring washers. These are the type of spring washers which are split. My reply was that I would not, and I thought that I would just review the reasons why I believe that all the evidence points towards them being ineffective. It was also a perfect opportunity to add to the information on this page.

There are two claims traditionally made for this washer:

1. The use of the washer facilitates the locking of the assembly so that self-loosening is prevented.

2. When the nut/bolt compresses the washer the spring rate of the joint is affected so that it will become more resistant to relaxation and fatigue.

Both of these claims can be misleading, at best. As long ago as 1969, Gerhard Junker (of Junker test fame) wrote a technical paper on his theory of self-loosening that showed experimentally that helical spring washers failed to prevent bolt loosening. In his paper he showed that preloaded fasteners self-loosen when relative movement occurs between the mating threads and the fastener bearing surface under the action of transverse joint loading. Helical spring washers fail to prevent fastener rotation arising from such movement. Since then, tests have shown that helical spring washers can result in the loosening rate of nuts being increased rather than prevented. The graph shows the results from the Junker test on plain nut alone and plain nut with a helical spring washer.

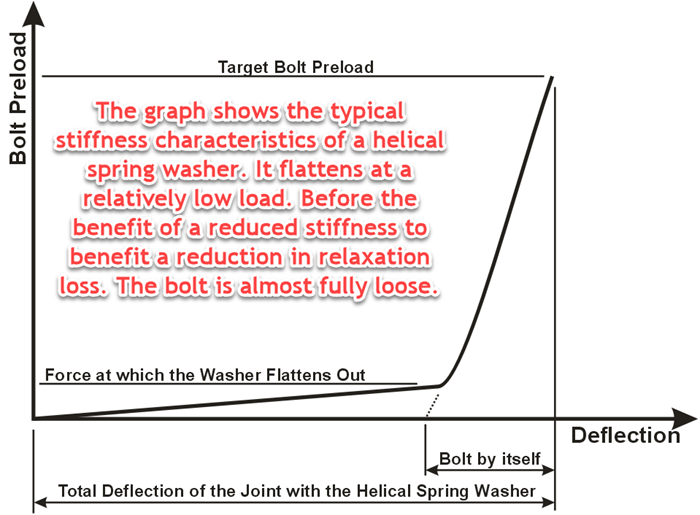

On some installations a plain washer is placed between the joint and the helical spring washer. The intention of this practice is to attempt to use the spring rate of the washer to beneficially change the stiffness characteristics of the joint. Having a greater amount of elastic deformation in a joint is beneficial since it will tend to reduce the effects of relaxation that can be particularly pronounced on small grip lengths. Such stiffness changes can also be beneficial in reducing the proportion of any axial applied load that is sustained by the bolt. Such reduction in bolt loading will enhance its fatigue resistance. However, one issue of using helical spring washers in this manner is that they tend to flatten out at a relatively low bolt preload. The deflection characteristic of a joint that includes a helical spring washer is shown in the image. Typically, such washers flatten out at between 10% to 20% of the target preload when fasteners of property class 8.8 and above are being used. Any embedding/relaxation that occurs to the joint will reduce the target bolt preload by a similar amount as if a washer had not been fitted. It is the stiffness rate at the preload that is of crucial importance. Normally it is desirable to have a low stiffness bolt in order that the proportion of any applied load that will be sustained by the bolt is reduced and hence its fatigue performance improved. However, it is again the stiffness at the target preload value that is crucial, and the fitment of a helical spring washer plays no part in affecting this and hence is of no benefit.

There are washers that are specifically designed to change the bolt/joint spring rate. For example, one such type of washer is the conical spring washer (which is a thick Belleville washer) to the appropriate standard, such as the German standard DIN 6796, are designed to prevent loosening of the assembly by relaxation/embedding. They are designed to flatten out close to the target preload and so, unlike helical spring washers, have a beneficial effect in reducing losses from such settlement.

During the testing of the helical spring washer, it has also been noted that some washers start to split apart during the tightening process. This seems to occur when the washer is flattened, and it partially, or fully, digs into the nut or bolt surface.

It is not only on the test bench that this type of washer is shown to be ineffective. By failing to prevent self-loosening, they have contributed to accidents occurring. For example, one such accident occurred on Friday 23 February 2007 when a high speed train derailed on points in the UK. Helical spring washers had been used on joints holding the points together that resulted in the nuts becoming completely detached from bolts which ultimately led to the train being derailed whilst it was travelling at speed. Bolt Science have investigated other accidents in which helical spring washers have failed to prevent loosening of bolts occurring.

In a publication in 2004, the German standards body Deutsches Institut fur Normung (DIN) published a document explaining why a range of standards covering so called lock washers (including helical spring washers) had been withdrawn. The withdrawal of the standards was done so that Designers would be discouraged from specifying them since they had been shown to be ineffectual in either resisting self loosening or effectively altering the spring rate of the joint. At the time they received criticism from many quarters which led them to conclude that many people were unaware of the state of technology for locking devices.

Hence considering all the above reasons you can appreciate why I will not recommend the use of such washers. The most effective way to prevent loosening is to design the joint and then assemble it correctly. Although there are effective locking methods, if the joint repeatedly sustains forces such that the joint moves, the bolts may not self loosen but they will fail as a result of fatigue or wear. Hence, there is no substitute for designing the joint correctly.

Bolt Science is a provider of training courses on bolting. Our training includes details of the theory under what circumstances bolts can self-loosen, and the loosening resistance of the major locking methods available (videos of Junker tests). Our training also covers how to complete a joint analysis that will allow the elimination of the tendency of bolts to self-loosen.For further details on this training, click here!

During the testing of the helical spring washer, it has also been noted that some washers start to split apart during the tightening process. This seems to occur when the washer is flattened, and it partially, or fully, digs into the nut or bolt surface.

It is not only on the test bench that this type of washer is shown to be ineffective. By failing to prevent self-loosening, they have contributed to accidents occurring. For example, one such accident occurred on Friday 23 February 2007 when a high speed train derailed on points in the UK. Helical spring washers had been used on joints holding the points together that resulted in the nuts becoming completely detached from bolts which ultimately led to the train being derailed whilst it was travelling at speed. Bolt Science have investigated other accidents in which helical spring washers have failed to prevent loosening of bolts occurring.

In a publication in 2004, the German standards body Deutsches Institut fur Normung (DIN) published a document explaining why a range of standards covering so called lock washers (including helical spring washers) had been withdrawn. The withdrawal of the standards was done so that Designers would be discouraged from specifying them since they had been shown to be ineffectual in either resisting self loosening or effectively altering the spring rate of the joint. At the time they received criticism from many quarters which led them to conclude that many people were unaware of the state of technology for locking devices.

Hence considering all the above reasons you can appreciate why I will not recommend the use of such washers. The most effective way to prevent loosening is to design the joint and then assemble it correctly. Although there are effective locking methods, if the joint repeatedly sustains forces such that the joint moves, the bolts may not self loosen but they will fail as a result of fatigue or wear. Hence, there is no substitute for designing the joint correctly.

Bolt Science is a provider of training courses on bolting. Our training includes details of the theory under what circumstances bolts can self-loosen, and the loosening resistance of the major locking methods available (videos of Junker tests). Our training also covers how to complete a joint analysis that will allow the elimination of the tendency of bolts to self-loosen.For further details on this training, click here!

Other content related to this pages content is presented below:

Why

nuts and bolts come loose Why

nuts and bolts come loose

Poster

on why nuts and bolts can come loose Poster

on why nuts and bolts can come loose

Video

- Junker Fastener Vibration Test Video

- Junker Fastener Vibration Test

Tests

on the double nut system of locking Tests

on the double nut system of locking

Vibrational Detachment

of Threaded Fasteners Vibrational Detachment

of Threaded Fasteners

Non-Rotational Loosening of Nuts and Bolts Non-Rotational Loosening of Nuts and Bolts

Preload Loss from Embedding in Bolted Joints Preload Loss from Embedding in Bolted Joints

Preload Loss from Stress Relaxation in Bolted Joints Preload Loss from Stress Relaxation in Bolted Joints

Bolt Self-Loosening and the Critical Slip Distance Bolt Self-Loosening and the Critical Slip Distance

|